Who We Are?

Experts with 25 Years of Operational Mastery

With over 25 years of hands-on experience, we specialize in delivering high-quality plastic manufacturing solutions that combine precision engineering, operational efficiency, and consistent quality.

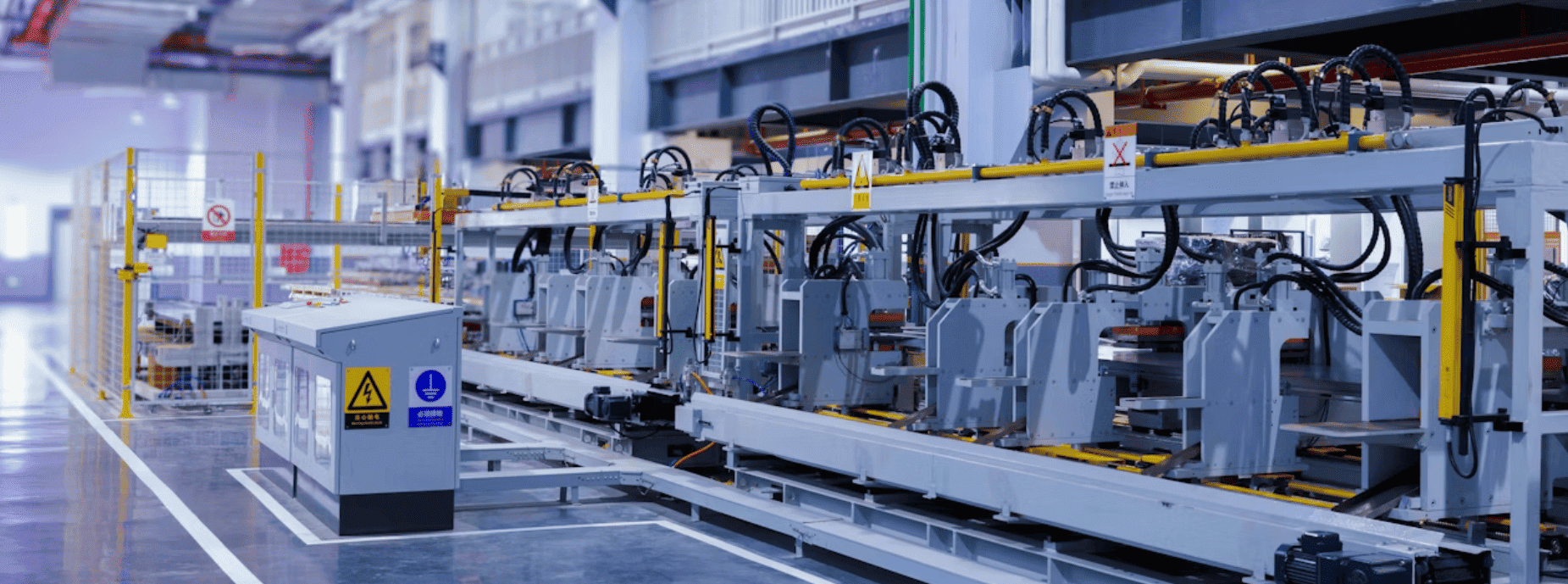

Manufacturing

We specialize in precision plastic manufacturing using advanced machinery and quality-driven processes.

Trading

We supply high-quality plastic products and raw materials to meet industrial and commercial demands.

Consultation

Our consultation services help businesses improve manufacturing efficiency.

Custom Solutions for Moulds, Machines & Materials

Tailored Mould Design

We design and develop custom plastic moulds engineered for production efficiency. Each mould is crafted to meet product requirements, ensuring smooth operation and reduced material wastage.

Precision Machines

Our manufacturing process is powered by modern, high-precision plastic processing machines that deliver consistent quality and scalable output. We focus on accuracy, speed, and energy-efficient operations.

Quality Materials

We work with carefully selected, high-grade plastic raw materials to ensure strength, durability, and compliance with industry standards. Material selection is tailored based on performance Custom Solutions needs.

Cost Reduction

Setup Time Cut

Years Experience

Satisfied Clients

Consultation for Greenfield & Brownfield Plastic Projects

Greenfield Projects

We support clients from concept to commissioning by designing efficient, scalable, and future-ready plastic manufacturing plants.

- Project feasibility & capacity planning

- Plant layout & workflow design

- Machine and mould selection guidance

- Raw material and utility planning

- Quality, safety & compliance setup

Brownfield Expansion

We help existing plastic manufacturers enhance capacity, improve efficiency, and modernize operations without disrupting ongoing production.

- Capacity expansion & line balancing

- Process optimization & waste reduction

- Machine upgrades & automation planning

- Cost-efficiency and productivity improvement

- Quality improvement & standardization

Why Choose 20 Lean Engineering?

Deep Industry Knowledge

Backed by decades of experience in plastic manufacturing. We understand real-world challenges and deliver practical.

Measurable ROI

Every solution is designed to improve efficiency, reduce waste, and lower costs. Our focus is on results you can measure and value you can see.

Hands-On Approach

We work closely on the shop floor, not just on paper. From planning to execution, we stay involved at every stage.

Sustainable Practices

Our processes prioritize energy efficiency and material optimization. We help build manufacturing systems that are responsible and future-ready.

Long-Term Partnership

We don’t stop at project delivery. Our team supports continuous improvement and long-term operational success.

Custom-Built Solutions

Every project is designed around your specific product, process, and capacity needs.only solutions that fit your manufacturing goals.

Our Process: From Assessment to Transformation

Assessment

We evaluate your current processes, capacity, and challenges.

Collaborative Design

We co-create solutions tailored to your product, plant, and goals.

Implementation

We execute the plan with hands-on involvement on the shop floor.

Continuous Improvement

We monitor performance and refine processes over time.